RESERVOIR AND APPURTENANT STRUCTURES

Reservoir and Appurtenant Structures (RAS) Group undertakes studies for evolving efficient, economical and safe hydraulic designs of spillways and energy dissipators, water conductor systems and other appurtenant structures such as protection works, high head gates, sluices and outlets, surge tanks, tunnels, penstocks, galleries, sedimentation and flushing of reservoirs, sediment control and exclusion devices. The studies are carried out with the help of hydraulic models, mathematical models and desk studies. There are four technical divisions under this discipline viz. Spillways and Energy Dissipator (SED), Control Structures and Water Conductor Systems (CSWCS), Sediment Management (SM) and Hydraulic Analysis and Prototype Testing (HAPT).

Spillways and Energy Dissipators (SED)

SED Division was established in 1958 to study the spillways of dams constructed immediately after independence, for irrigation, generation of power and flood control. Many of the projects taken up in early years such as Bhakra, Hirakud and Koyna were among the large dams in the world and involved several complex problems. So far model studies for more than 150 projects have been carried out both in India and abroad.

Major Research Activities

- Approach flow conditions upstream of spillway

- Assessment of discharging capacity with full and partial gate openings

- Pressures on spillway and design of aerators

- Observations of water profiles for design of training walls, divide walls and location of trunnion beam

- Performance of energy dissipating arrangement

- Scour downstream of energy dissipator and plunge pool design

- Construction stages of spillway

- Protection works near spillway

- Assessment of prototype performance

.jpg)

Control Structures and Water Conductor Systems

Major Research Activities

- Layout, location and dimensions of power intake

- flow conditions in the vicinity of intake

- Transient analysis for water hammer effect and water level variations in surge shaft

- Flow conditions in head race channel / tunnel

- Tailrace Channel / tunnel: layout and alignment, flow conditions and velocity distribution, and draft tube submergence

- Gates & Stoplogs: overall layout, hydrodynamic uplift and downpull forces, and air demand downstream of gates

- Air water column separation and assessment of necessity of airvents

- Flow conditions and water levels in surge shafts

Sediment Management

Flushing of Sediment from Reservoirs

When a dam is constructed across a stream to form a reservoir, the velocity of flow entering the pool reduces and the major part, or all, of the sediment transported into the reach deposits in the backwater region of the reservoir, Thus, the sedimentaton in the reservoir is inevitable. Most of the majaor reservoirs are generally designed to provide sufficient storage to hold a 100 year's accumulation od sediment without encroaching upon the storage provided for the functional operation.

Out of the total utilizable hydro potential of India, 78% lies in Himalayan regions. The ideal locations for new reservoirs for hydropower generation have already been utilized and sites are available only in Himalayan and North East regions. Most critical technical problem associated with the construction of head works on the mountainous streams is the interaction of water and sediment. The Himalayan rivers flow through narrow and deep valleys and carry huge quantity of sediment during monsoon season. When storage reservoirs are constructed on these rivers, the sediment settle down in the reservoir and the capacity of reservoir to store water is lost within a few years (2 to 10 years). To overcome this critical technical problem, the concept of run-of-the-river schemes has been developed during the recent years. In the run-of-the-river schemes, reservoir is designed with minimum storage capacity for functional requirements and with facilities to disposal of the deposited sediment at regular intervals. Storage capacity of the reservoirs is maintained by proper sediment management. Sediment management can be achieved by the technique of hydraulic flushing/ sluicing of reservoirs.

For hydraulic flushing/sluicing of reservoirs, spillways of dams are provided very near to the river bed. The sediment deposited in the reservoir is passed through the spillways by opening the gates when sufficient water is available. During sluicing, water level is maintained at minimum draw down level and heavy sediment concentrated flow is passed downstream through the low level outlets during high flows, before it gets deposited in the reservoir. Sediment flushing is to use flow to remove already existing reservoir sediment deposit. When the water level in the reservoir is high only a local flushing cone is formed and the flushing process is not very effective. However when the water stage is low, the flushing of sediment can be very effective to remove previously deposited sediment and also to pass sediment in the flow if the sediment deposit has reached to a location very close to the dam. This is commonly known as drawdown flushing and retrogressive erosion can occur. A flushing channel usually develops during drawdown flushing especially for wide reservoirs. Sediment flushing can be very effective in run of the river reservoirs in narrow gorges due to the steep bed slopes and natural river like flow conditions. Hydraulic flushing is generally applied to medium and small reservoirs, since reservoirs are required to be emptied for effective flushing.

Model studies are being carried out at Central Water & Power Research Station (CWPRS), Pune, for optimizing the design of various components of hydropower projects. A satisfactory design of any run-of-the-river scheme can be developed only with aid of a series of model studies. Mathematical and physical model studies are successfully applied to solve the problems pertaining to the efficient flushing of sediment vis-à-vis functioning of the spillway/ outlet, energy dissipators, desilting basin and flushing tunnel beyond desilting basin. Hidden problems in the design can be easily identified through model studies and accordingly one can modify the design. One-dimensional numerical modeling is useful in predicting the rate and pattern of sediment deposition in the reservoir. This constitutes an important input for the studies in a physical model to evolve suitable arrangement of spillway/outlet in relation to the power intake and finalize the operating conditions for effecting flushing of sediment. Model studies for more than 20 projects have been conducted at CWPRS for flushing of reservoirs; a few important examples of such projects are Nathpa Jhakri (Himachal Pradesh-India) , Kurichu (Bhutan), Tala (Bhutan), Chamera II (Himachal Pradesh-India), Subansiri Lower (Arunachal Pradesh-India), Parbati stages II and III (Himachal Pradesh -India), Dhauliganga (Uttarakhand-India), Teesta-V (Sikkim-India) Teesta Low dam projects Stage III and IV (Sikkim-India), Kotlibhel stages IA, IB and II (Uttarakhand-India), Devsari (Uttarakhand-India), Punatsangchhu I and II, Arun-III (Nepal) and Mangdechhu (Bhutan).

.jpg)

Mangdechhu Reservoir Model after flushing

Nathpa Jhakri Reservoir during flushing

Sediment Management in Water Conductor Systems

In the case of hydro electric projects, heavy sediment load particularly sharp edged silt/sand, may lead to damage of the turbine runner blades/ buckets due to abrasion resulting in decrease in the efficiency of the power plant. It has been observed that in some projects, the turbines have been damaged after 2000 to 3000 hours of operation and required to be repaired twice in a years. This results in shut down of the units for considerable duration thereby causing enormous loss of power and revenue. The silt / sand particles entering the water conductor system is to be removed by providing desilting basins.

Several studies had been carried out at CWPRS for various types of desilting basins. Two technical Memorandums published providing the guidelines for the design and operation of the desilting basins.

During the earlier days sediment excluders were provided in barrages to reduce sediment entry into the canals and sediment ejectors were provided in the canals to remove the sediment entering the canals. In the case of hydroelectric projects, different types of desilting basins are used to remove sediment particles. It is possible to achieve the desired efficiency by adjusting the shape and size of the basin for obtaining the required settlement of sediment particles.

Water conductor system for the Trishuli Power Project, Nepal comprises of a 3.25 km long power channel. A balancing reservoir with a live storage capacity of 0.25 Mm3 was provided to take care of the fluctuations and dead storage capacity of 0.45 Mm3 was provided for sediment deposition. However, in the first three years of commissioning of the project in 1967, sediment deposition occupied to 20 % of the dead storage. Studies were conducted at CWPRS to evolve an efficient sediment exclusion system. Studies conducted on a 1:20 GS scale model indicated that a 33 m wide and 170 m long desilting basin provided just upstream of the balancing reservoir would give about 91 % of settling efficiency for sediment coarser than 0.075 mm. For flushing of the deposition from desilting basin 5 low level outlets were provided. The desilting basin was provided with a steep bed slope of 1:24 and the deposition could be flushed in about 45 minutes. With the above arrangement the life of reservoir could be increased to 100 years. The desilting basin has been commissioned in 1975 and has since has been working satisfactorily. The system is an intermittent type of desilting basin, since the supply to the balancing reservoir is cut off during flushing and power generation is maintained by the supply from the balancing reservoir.

In the run-of-the-river power projects, water conductor systems and power houses are generally provided underground in tunnels. Open type desilting basins can even be adopted for the desilting basins in tunnels if site conditions are favourable. However, considering the size of the basins, rock conditions and economy, pressure type desilting basins are preferred in most of the cases. Such a pressure flow type desilting basin was provided in Chukha HE project, Bhutan. Model studies were carried out at CWPRS on a 1:25 GS scale model to optimize the design of the desilting system. The silt flushing arrangement was modified by providing a silt flushing tunnel below the desilting basin. Openings of sufficient size and spacing were provided on the floor of the settling trench of the desilting basin. Model studies indicated that 348 m long desilting basin would be adequate for removal of 90 % of sediment coarser than 0.2 mm.

Model of silt flushing tunnel beyond desilting basin

Model of silt flushing tunnel beyond desilting basin

Subsequently during 2000-2015, model studies were carried out for desilting basins and silt flushing tunnels of a number of hydro electric projects in India and abroad. Some important projects for which studies were carried out at CWPRS are: Nathpa Jhakri, Tala, Chamera, Teesta-V, Sewa, Uri, Parbati, Punatsangchhu, Teesta-IV, Mangdechhu, Etalin etc. For all the above projects the design of desilting basin was optimized in respect of inlet and outlet transition, desilting basin length, size of flushing trench, size, number and spacing of openings for discharging sediment into the silt flushing tunnel. The size, slope, manifold arrangements of silt flushing tunnels were also optimized on the basis of model studies conducted at CWPRS.

Key Projects Studied:

1. Mangdechhu H.E. Project, Bhutan

- Model studies for reservoir sedimentation and flushing

- Studies to optimise reservoir flushing schedule

- Result of studies utilised to finalise alignment of power intake and spillway crest level

.jpg)

2. Arun III H.E. Project, Nepal

- Model studies for reservoir sedimentation and flushing

- Mathematical and physical model studies for reservoir sedimentation utilised for finalising the design of project components (spillway and intake)

- Final design adopted based on the model studies excluded the desilting basins which helped in huge saving of overall project cost

- Model studies also conducted to optimise the reservoir flushing schedule

List of Projects in hand:

Ongoing and completed studies:

- HMS for reservoir flushing for Devsari H E Project, Uttarakhand

- HMS for reservoir flushing for Dhaulasidh H E Project, H P

- HMS for reservoir flushing for Mangdechhu H E Project, Bhutan

- HMS for reservoir flushing for Dri limb -Etalin H E Project, Arunachal Pradesh

- HMS for reservoir flushing for Punatsangchhu -II H E Project, Bhutan

- HMS for reservoir flushing for Arun - III H E Project, Nepal

- MMS for reservoir sedimentation for Punatsangchhu -II H E Project Bhutan

- MMS for reservoir sedimentation for Dri limb -Etalin H E Project, Arunachal Pradesh

- MMS for reservoir sedimentation for Tangon limb -Etalin H E Project, Arunachal Pradesh

- MMS for reservoir flushing for Arun-III H E Project, Nepal

Proposed studies:

- HMS for reservoir flushing for Tawang -I H E Project Arunachal Pradesh

- HMS for reservoir flushing for Tawang –II H E Project Arunachal Pradesh

- HMS for reservoir flushing for Lata-Tapovan H E Project Uttrakhand

- HMS for reservoir flushing for Teesta –IV H E Project, Sikkim

- HMS for reservoir flushing for Thana Plaun H E Project, Himachal Pradesh

- HMMS for reservoir sedimentation for Thana Plaun H E Project, Himachal Pradesh.

- H MMS for reservoir sedimentation for Kali Gandaki Koban H E Project, Nepal

- H MMS for reservoir sedimentation for Upper Siang H E Project, Arunachal Pradesh

- HMMS for Chukha H E Project, Bhutan

HAPT

I. Hydraulic Model Studies for Barrages:

For important barrages, it is necessary to carry out model studies to get comprehensive idea regarding hydraulic conditions and layout of the barrage including its appurtenant structures. Many aspects of a barrage are finalized after detailed study of different alternatives on a model. The major aspects of a barrage which could be finalized in the model after studying different alternatives are:

(a) Orientation and waterway of the barrage

(b) Location of the abutments with respect to the river banks

(c) Shape and level of the crest

(d) Optimum length of divide wall both on upstream and downstream

(e) Position of the canal entry point

(f) Alignment and lengths of the guide bunds

(g) Energy dissipation arrangements in both spillway and under sluice bays

(h) Level and lengths of the stilling basins

(i) Silt excluder details such as length, number of bay, etc.

(j) Gate operation schedule

(k) Alignment of approach embankments and afflux bunds

.jpg)

.jpg)

Narrage barrage studies

1D/2D Numerical model studies / Physical model studies will be carried out for suitable reach for the following components:

(a) study alternative sites and layouts for the barrage to ensure technical soundness and recommend the appropriate site supported by site inspection, desk studies and analytical computations, physical and mathematical model studies for the barrage;

(b) determine pond level, storage area and all other parameters of the barrage;

(c) study the backwater effect;

(d) establish design criteria for designing the barrage, river training works, afflux bunds, other major structures, and facilities of the project

II. Model Studies for Flood Protection Works:

A number of small rivers (Khad) flow through the mountainous valley of Kangra district and finally joins river Beas in Himachal Pradesh. The Khads in turn are fed by a number of streams, which after emerging as small torrents from the hill slopes meet the main river at the plains resulting in delta like formations. The streams carry large quantity of sediment load which due to the flatter slope in the plains, deposits along the river bed resulting in aggradation and meandering of the Khads. The river experiences typical flashy floods during monsoon and due to the low banks, inundates the agricultural land along both the banks. Flood protection works in the form of levees/bank pitching are require along both the banks. There are no established rain/river gauging stations in the catchment of these streams and hence alternate methods are required for estimating the design discharge and other hydraulic design parameters for flood protection works. Integrated application of remote sensing, GIS and mathematical modelling techniques are employed for design of flood protection embankments for ungauged rivers and catchments.

III. Mathematical Model Studies for Rivers:

River hydrodynamics and morphological changes of major rivers (wide rivers) are required to be studied using 2-D numerical models. 2-D numerical model simulations are generally required to simulate/estimate the water levels, velocity distribution and sediment deposition/scour along these rivers. The above parameters are required for designing flood protection/river training works, locating of hydraulic structures etc.

IV. Mathematical Model Studies for Hydro Electric Projects:

Recently many hydroelectric power projects are being developed in the upper reaches of Himalayan Rivers. The projects are designed as Run-of-the-river schemes to sustained project life by sediment management. Reservoir flushing/sluicing techniques are used to remove sediment deposition and sustain reservoir capacity. The sedimentation levels along the reservoir are to be predicated/estimated for design of various project components such as spillways, power-intake and water conductor systems. The sediment deposition pattern in the reservoir is to be predicted from long term simulations of sediment transport. Since the reservoirs are elongated and gorge type, 1-D numerical models are applied to predict the long term deposition pattern in the reservoirs of run-of-the-river hydropower projects. 2-D/3-D numerical models are used for predicting the sediment deposition levels in the vicinity of hydraulic structures such as spillways and intakes. Hence, an integrated approach of 1-D numerical model for long term simulation of sedimentation in the entire reservoir and 2-D/3-D numerical model to predict the near field phenomena such as for bed profiling in front of power intake and its vicinity are used in the studies.

Key Projects Studied:

1. Flood protection for Majuli Island and Brahmaputra River

- Model studies for design of flood protection works

- Alternative alignments of guide bunds for protection of Majuli Island from floods of River Brahmaputra

- Participation in Technical Advisory Committee (TAC) for flood protection of River Brahmaputra

- Suggesting short term and long term flood protection measures for River Brahmaputra at various location in Assam and Meghalaya

Construction of Spur for protection of Majuli Island

RCC Porcupines for protection of Majuli Island

2. Polavaram Project, Andhra Pradesh

- Model studies for scour due to construction of diaphragm wall and spill channel <o:p>

- Mathematical model studies for estimation of scour due to construction of diaphragm wall for Earth and Rockfill (ECRF) Dam

- Suggesting suitable protection works required to safely pass the monsoon flood of River Godavari over already constructed diaphragm wall

- The diaphragm wall constructed upto 1.5 m below river bed for about 800 m of ECRF Dam and the 2017 flood safely passed without any damage to the diaphragm wall

- Studies helped in maintaining Project construction schedule and construction of ECRF Dam

Construction of diaphragm wall of ECRF Dam, Polavaram Project

3. Kwar H.E. Project, Jammu and Kashmir

- Model studies for reservoir sedimentation and sluicing

- Spillway crest level finalised based on above studies

- Results of model studies utilised to obtain technical clearance of Project from Central Electricity Authority (CEA) and Central Water Commission (CWC)

4. Kishanganga H.E. Project, Jammu and Kashmir

- Hydraulic model studies for reservoir sedimentation and sluicing

- Spillway crest level finalised based on above studies

- Results of model studies utilised to defend Indian design in arbitration filed by Pakistan

Kishanganga Dam and Intake

List of Projects in hand:

Ongoing and completed studies:

- 2D Hydraulic Model Studies for reservoir sluicing of Kishanganga HE Project, Jammu & Kashmir

- Hydraulic 3D-Model Studies for reservoir sluicing, Kishanganga HE Project, Jammu & Kashmir

- Hydraulic model studies for flushing of sediment from Tangon reservoir, Etalin HE Project, Arunachal Pradesh

- Hydraulic Model studies for reservoir flushing of Pakal Dul H.E. Project(1000MW), Kishtwar, J&K.

- Hydraulic Model Studies for reservoir flushing of Kholangchhu HE Project, Bhutan

- Mathematical model studies for flood protection measures of Beas river from Pong dam headworks to Mirthal bridge, Himachal Pradesh

- MMS for reservoir flushing of Kholangchhu HE Project, Bhutan

- Mathematical Model Studies for protection work of spill channel, Polavaram Project, Andhra Pradesh

- Mathematical Modeling of Scouring of Diaphragm Walls of Polavaram Earth Dam, Andhra Pradesh.

- Ratle HEP(850 MW),J&K Numerical Model studies for Reservoir sedimentation, J&K

- Mathematical Model studies for reservoir flushing of Pakal Dul H.E. Project (1000MW), Kishtwar, J&K.

Proposed studies:

- Mathematical Model Studies for Reservoir Sedimentation of Panan H E Project, Sikkim

- Hydraulic model studies for reservoir flushing of Panan H.E. Project, Sikkim

- MMS for Brahmaputra pilot channel studies, Assam

- Mathematical Model Studies for Raison H E Project, Kullu, HP

- Hydraulic Model Studies for Teesta barrage project, WB

- Mathematical Model Studies for Teesta and Mahananda and TMLC, WB

- Mathematical Model Studies for Bhadbhut barrage, Gujarat

- Mathematical Model Studies for Brahmaputra barrage, Bangladesh

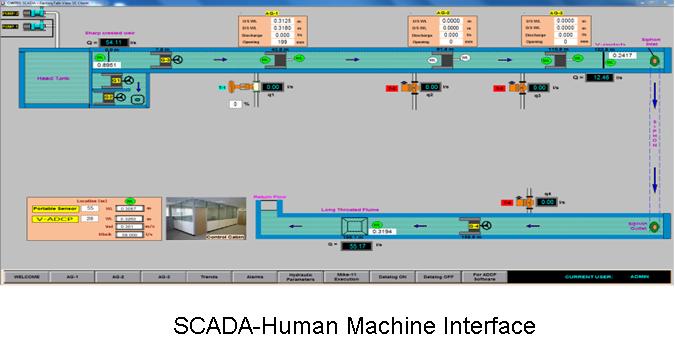

AUTOMATION OF MODEL CANAL

Canal Automation helps to provide high level of services to water users by supplying consistent flows at requested time, place, rate and duration in transparent manner. It facilitates efficient water conveyance by minimising operational losses, thereby reducing the operational cost. It uses hydraulic analysis for determination of various canal flow related parameters, associate technologies to digitally measure water levels, flow rates and gate movements as well as robust communication system to transmit and receive monitored data and necessary instructions.

Prime objectives of automated model canal are to demonstrate centralized automated controls for canal operations, training of field engineers & academicians and its use as a research platform.

The model canal has been designed to extract maximum benefits from advances made in information & communication technologies and hydraulic analytical tools for efficient management of water. A 190 m long rectangular model canal has been equipped with advanced metering infrastructure of acoustic flow meters and water level sensors with modern telemetry for remote monitoring and control. All canal control functions have been integrated with Supervisory Control And Data Acquisition (SCADA) system for its real-time operations.

FLOW MEASUREMENTS

Accurate automated flow measurements at critical locations are essential element of modern irrigation systems. Conventional hydraulic flow measurement devices have been SCADA enabled through acoustic water sensors. Acoustic water level sensors and flow meters have been installed in the model canal for precise flow measurement.

Many new flow measurement technologies are developed with easy SCADA integration in mind, but older devices still make up a significant part of canal flow monitoring network. Long throated flume, sharp crested weir and V-notch have been installed as flow measurement devices and their rating equations have been incorporated into SCADA. V-ADCP - a portable flow meter and Electromagnetic Flow meters have been installed for comparison, calibration and demonstration purposes. These equipments can be provoked through SCADA for their operations and observational displays.

AUTOMATIC GATES

The major control elements in the model canal are three automatic sluice gates with flow measurement features. The gates can be operated locally through touch-pad and LCD push button display or remotely through SCADA. Ten acoustic water level sensors are installed at upstream and downstream of the gates and flow measurement sites.

At upstream of three automatic gates, an orifice type turnouts fitted with SCADA operated remotely controlled motorized valves have been installed to simulate canal branches.

SCADA

SCADA provides a human-machine interface (HMI) for collecting, storing and displaying real-time data, managing the defaults, alarms, and allowing remote control and monitoring of automatic gates and turnout valves devices.

Control of equipments, exchange of instructions is implemented through Programmable Logical Controller (PLC.) controlled telemetry.

Discharge measurment in River & Canal

The management of water resources depends, to a considerable degree, on the availability of hydrological and hydraulic data. The operation and maintenance of irrigation systems requires collecting regular data on water levels and discharges. The calibration of canal sections or structures provides information on canal discharges and hence supports the efficient day-to-day water management and regulation of irrigation systems.

CWPRS conducts various studies for flow measurements using current meter and advance measurement system like Acoustic Doppler Current Profiler (ADCP) using River Surveyor instrument. The ADCP is an acoustic instrument designed to measure discharges in river/canal, three dimensional water currents, depths and bathymetry from a moving or stationary vessel. Water-velocity measurements are made by transmitting sound at a known frequency into the water and measuring the doppler shift, or change in sound frequency, from signals reflected of particles in the water.

The primary advantages of making discharge measurements using the ADCP, as compared with point velocity meters such as the current meter are that the time required to complete a measurement is reduced, the ADCP allows for data to be collected throughout most of the water column and cross section rather than at discrete points, the ADCP is deployed at the water surface appreciably reducing the chance of snagging by debris, the instrument can be boat-mounted thus, eliminating the installation, maintenance, and liability of costly manned cableways/cradle arrangement.

Projects:

CWPRS conducted various studies in Tungabhadra Project, Sardar Sarovar Narmada Nigam Limited, Delhi Jal Board etc., which are of interstate water distribution projects through these canals.